As a component of future factories, traditional industrial manufacturing workshops are beginning to move towards intelligence. Intelligent factories perform real-time data analysis by obtaining information on customer needs, production status, raw materials, personnel, equipment, production processes, environmental safety, etc., thereby achieving automatic decision-making and precise command execution. Industry insiders once asserted that "industry does not need the internet." Because industrial production emphasizes standardization and process, this seems to be completely different from the openness of the internet. In the past two years, artificial intelligence technology has gradually been applied to industrial production, and artificial intelligence factories have also begun to spread globally and continuously improve and mature. By definition, an intelligent factory is a factory that combines traditional manufacturing factories with information technology (IT) to improve production efficiency.

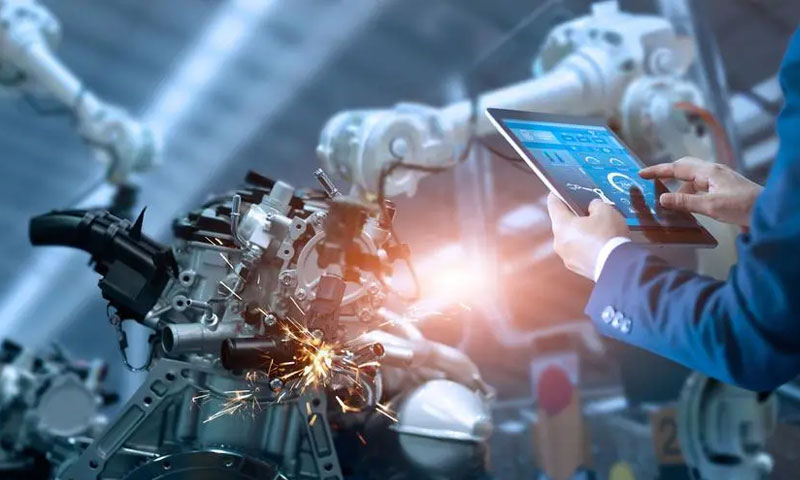

In future intelligent factories, each production process is clearly visible and highly transparent: information and production form a closely related network. The entire workshop operates quietly and efficiently, with intelligent machines not only collaborating with each other, but also with employees, customers, and customers worldwide, as well as intelligent analysis dynamic systems, distributed throughout various links of the entire supply chain. As a component of future factories, traditional industrial manufacturing workshops are also beginning to move towards intelligence. Through the network and software management system, CNC automation equipment can be interconnected. Intelligent factories can obtain information such as customer needs, production status, raw materials, personnel, equipment, production processes, environmental safety, etc. for real-time data analysis, thereby achieving automatic decision-making and precise command execution.

The entry of artificial intelligence into the workshop brings four major advantages: firstly, an efficient and flexible production mode. Implement intelligent manufacturing to promote the transformation from production methods to control modes, optimize process flow, reduce production costs, and promote the improvement of labor efficiency and production efficiency. The second is effective collaboration and integration of the industrial chain. Promote the application of intelligent manufacturing technology in the equipment manufacturing industry, promote seamless cooperation in the research and development, design, production, manufacturing and other aspects of the industrial chain, and lay the foundation for further improving the efficiency of industrial chain collaboration. The third is the new type of production service-oriented manufacturing. The implementation of intelligent manufacturing promotes the transformation from a productive organization to a service-oriented organization. Through the use of key technologies of intelligent manufacturing such as the Internet of Things, Big data, cloud computing, etc., new business models and service forms such as remote operation and maintenance, intelligent cloud services, etc. are constantly promoted, and innovation and service capabilities are comprehensively improved. The fourth is collaborative development and cloud manufacturing. Realize information sharing, integrate advantageous resources, implement collaborative innovation in various industrial chains, and promote the optimal allocation of manufacturing resources and capabilities to improve labor productivity and product quality.

While striving to achieve intelligent workshops, we are also steadily advancing towards intelligent factories and laying the foundation for intelligent manufacturing. In the era of digital manufacturing, the boundary between the physical world and the digital world has been dismantled, and replacing traditional manpower with intelligent technologies such as robots has become a trend. Artificial intelligence workshops will be the trend in China and even the world in the next 10 years, and will outline a new future for the manufacturing industry.