The manufacturing industry cannot do without molds, which are an indispensable and important component and the most basic mass production tool. When measuring the manufacturing level of a country, the output and accuracy of molds are important indicators. Although molds have been used in China for a long time, their formation of the industrial chain was still in the 1980s, and it can be said that the actual formation of the industrial chain was relatively late.

Although the formation of China's mold industry chain is relatively late compared to some developed countries in the West, it has developed rapidly. In just a few decades, it not only followed the international pace and entered digital production, but also became a major mold production country internationally.

Analysis of the Bottlenecks Encountered in the Development of the Mold Industry

Mold parts production

However, with the rapid development of the domestic mold industry, its shortcomings and bottlenecks have gradually emerged, which has made many enterprises and professionals in the mold industry feel the difficulty of developing in the mold industry. Although China is currently a major producer of molds in the world, it is still far from reaching the international advanced level in producing large, complex, precise, and long-life molds, or most enterprises are still difficult to achieve this. The reasons for this are multifaceted.

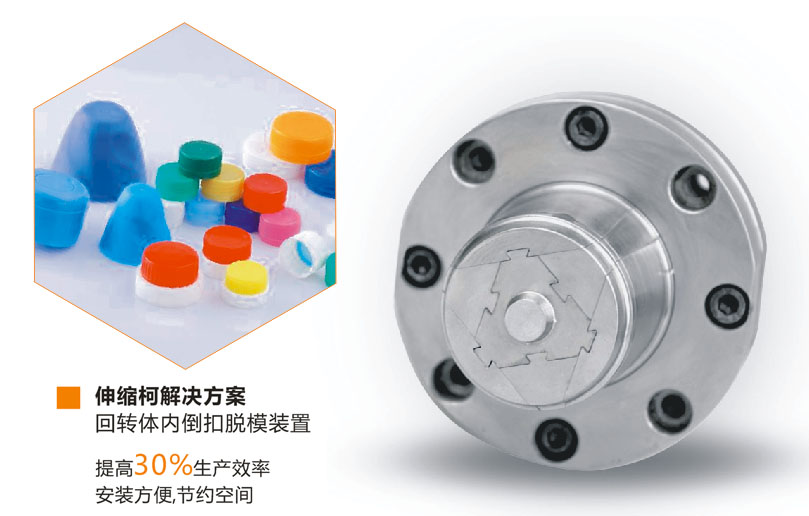

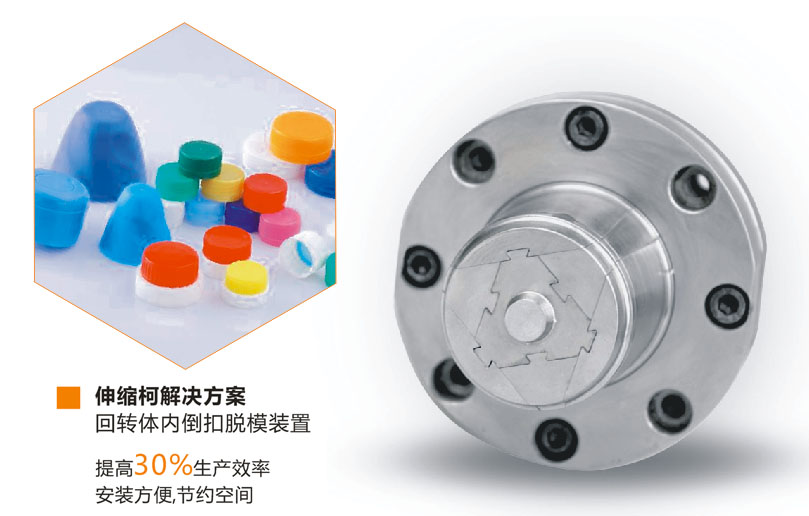

Plastic mold bottle cap thread removal product telescopic cap

The reasons for organic bed tools include processing technology, technology, talent, and enterprise management, as well as market orientation.

1. In terms of machine tools, compared to developed countries (such as Germany's machine tools), their technological content is not high enough, and processing accuracy also needs to be continuously improved. This greatly affects the accuracy and quality of mold processing.

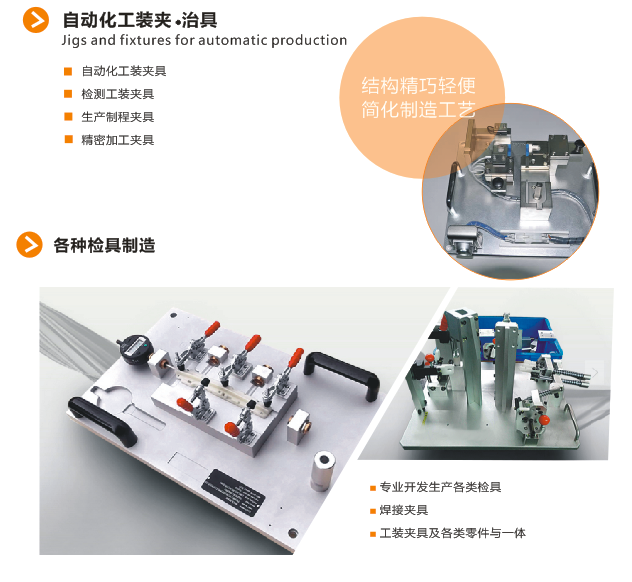

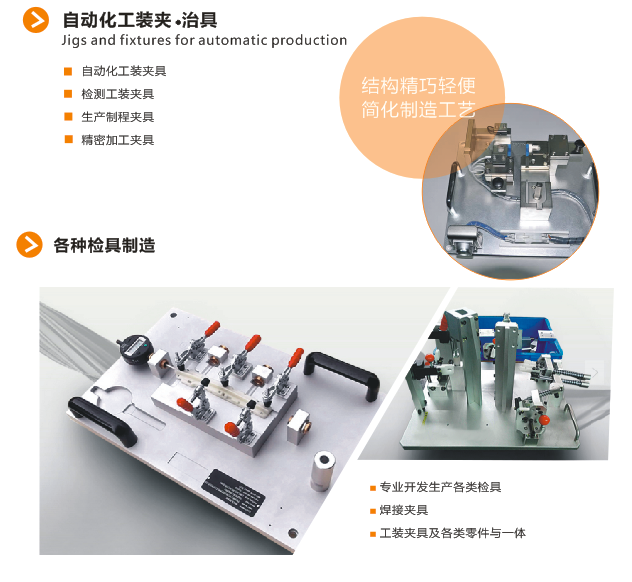

Clamp manufacturing

2. With the development of science and technology, the traditional processing technology has gradually been replaced by modern processing technology, such as the newly developed Electrical discharge machining technology and WEDM technology. Although it is an emerging technology, its time-consuming shortcomings in processing are gradually emerging, especially in slow wire cutting, which is even more time-consuming. So the updated processing technology has become a bottleneck that needs to be addressed even more in the industrial market.

3. Technological innovation is also crucial for improving the level of the mold industry, so it is completely correct for the country to implement the policy of revitalizing the country through science and education. Technological innovation is also a bottleneck in the development of the mold industry at present. As long as a mature and reliable technological innovation requires a large amount of manpower, material resources, financial resources, and a large time cycle, many enterprises are not willing to invest such huge costs, This leads to slow industry development. But this also provides huge development space for large enterprises with strength and willingness to invest resources. The core technology in the future will definitely be in their hands, playing an important role in the development of the mold industry.

4. Due to the bottlenecks encountered in the current development and upgrading process of the mold industry, and the fierce competition in this industry, it has become more difficult for many industry insiders to survive and develop in this industry. This has led to many talents who have been engaged in the mold industry for many years switching to other industries, resulting in talent loss and short-term pressure on the mold industry to some extent.

5. Due to the continuous shortening of the Makespan of the mold in the market, the production cycle of the mold has been shortened under the conditions of the original machine tool, process and technology, which will undoubtedly affect the precision and quality of the mold to varying degrees. So although China is currently a major producer of molds, there is a shortage of high-quality molds, resulting in a shortage of high-end molds and an oversupply of mid to low end molds.