Processing methods and processes of plastic molds

1. Common processing tools and machines

1) Measuring tools: calipers, micrometers, micrometers, standard gauge blocks, standard angle blocks, turntables, angle gauges, projectors, reading machines, etc;

2. Processing machines and equipment: gongs, lathes, grinders, drilling machines, CNC (computer gongs), spark machines, wire cutting machines, etc.

2) Processing methods and processes

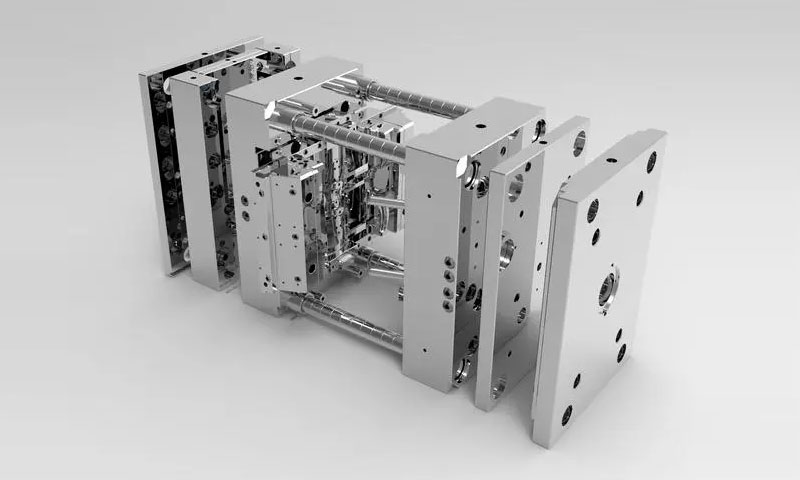

According to the mold design drawings, the steel materials such as the mold embryo, mold core, row position, inclined top, and inserts can be ordered back to start processing. According to processing technology, it can be roughly divided into two parts: rough machining and precision machining. The mold forming process involves first roughening and then refining the frame using a gong machine or computer gong (which can also be processed by a mold forming factory, but corresponding fees need to be paid; some small mold houses often process themselves to save costs, but with low efficiency and accuracy). Other components are also roughened into rough shapes and then processed by computer gongs, spark machines, and wire cutting machines to meet the accuracy requirements of the drawings, Finally, assemble the mold into a complete set of molds. The process is roughly as follows: mold opening frame - CNC machining of mold core, row position, etc. - copper machining - spark machining cavity (EMD) - fitter machining (FIT mold) - polishing (mold saving) - mold installation - mold trial.

In actual manufacturing, several processing techniques are intertwined, and it requires mold designers and mold masters to arrange each link properly. If one step goes wrong, everyone will bear the consequences! Rework often causes damage to the mold, and the resulting mold becomes unattractive. If we want to remedy it well, we can only replace it, which will increase time and cost, and often time is the most important. The competition in the mold industry is very fierce now, and customers are in a hurry to provide mold rooms. Failure to deliver the molds on time will ultimately result in losing customers!

Introduction to the functions of various processing machinery and equipment:

1. Gong machine, used for manual milling and cutting of workpieces with simpler and more regular shapes, such as straight lines and oblique lines; Commonly used for machining workpieces with low precision, such as mold opening, mold core, and line position cutting.

2. Lathe is mainly used for processing circular workpieces, such as nipples, locating rings, flanges, circular molds (CORE), circular copper pipes, etc; The accuracy can meet high requirements.

3. Grinder, mainly used for steel material grinding, grinding benchmark, etc., can meet most accuracy requirements.

4. Drilling machines are mainly used for drilling holes, tapping teeth, and drilling water holes.

5. CNC (computer gong) has become a landmark equipment in the modern mold industry, mainly used for CNC machining of complex and irregular surfaces. Its characteristics are high precision, good reliability, and high efficiency, and almost any mold processing cannot be separated from it. The machining of workpieces such as cavities and copper pipes is completed by it; It can process almost any shape of workpiece.

Computer gongs are controlled by computer programs, therefore, their operators - CNC programmers - should not only be familiar with computer gongs processing control software, but also have a deep understanding of mold structure and processing methods. A programmer who only understands machining software but does not understand mold structure and machining methods can only talk on paper. In the past two years, UG has become increasingly popular among mold processing manufacturers due to its convenient operation, good reliability, high efficiency, and good simulation performance, making its talents more sought after.

6. Spark machine, used for electro etching workpieces. Install the electrode (copper male) on the machine head and control the current discharge through the internal circuit of the machine to etch a concave cavity on the workpiece that is the same shape as the electrode. Mold terminology: EMD machining.

7. Wire cutting machine, used for cutting the shape of workpieces. It passes an extremely thin molybdenum wire through a pre drilled hole on the workpiece, controls the discharge and operation of the molybdenum wire according to the data in the computer, and cuts the set shape on the workpiece. The diameter of molybdenum wire is generally 0.07~0.10mm, therefore, its machining accuracy is also very high. Wire cutting is divided into fast wire cutting and slow wire cutting. Generally, the wire cutting machine in the mold room is a fast wire cutting machine,

Slow walking silk means that the processing speed is very slow. It sacrifices speed in exchange for high precision, which is basically used for processing precision molds and some hardware terminal molds. The unit price is 3-5 times that of fast wire. One detail that needs to be mentioned is that the water used for slow walking silk is pure water. Of course, it is also CNC and requires writing computer programs to control it.